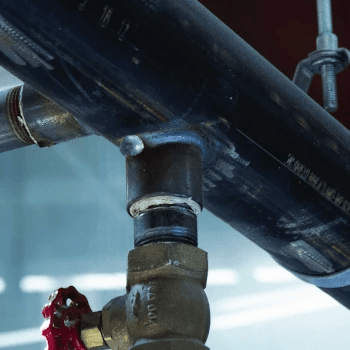

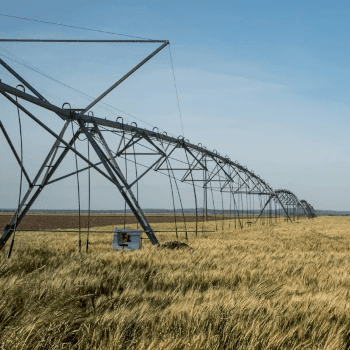

HDPE Piping for Mining Applications

HDPE (High-Density Polyethylene) pipes are commonly used in the mining industry due to their versatility and suitability for various applications. Some of the key uses of HDPE pipes in mining include:

Slurry Transportation

HDPE pipes are often used to transport abrasive and corrosive slurries in mining operations. Their resistance to abrasion and corrosion makes them ideal for conveying mineral-rich slurries and tailings.

Water Supply

HDPE pipes are used to transport water to various parts of mining operations, including for dust control, process water, and potable water supply to mining facilities.

Tailings Management

HDPE pipes are used to transport tailings from mineral processing plants to tailings storage facilities. Their durability and resistance to chemical and abrasive substances are critical for this application.

Dewatering

HDPE pipes are employed in dewatering applications to remove excess water from mining sites, allowing for more efficient and safe operations.

Piping for Heap Leach Operations

In heap leaching processes, HDPE pipes are used for the distribution of leach solution to ore heaps, allowing for the extraction of valuable minerals.

Process Water Supply

HDPE pipes are used for supplying process water to various mineral processing steps, such as flotation, crushing, and grinding.

Underground Mining

HDPE pipes can be used in underground mining operations for ventilation, water supply, and other applications due to their resistance to corrosion and lightweight nature.

Hydrotransport Systems

HDPE pipes are used in hydrotransport systems to move ore, slurry, and water mixtures over long distances, often involving rugged terrain.

Lining for Ponds and Tanks

HDPE liners and pipes are used to line ponds, tanks, and containment structures in mining operations to prevent seepage and protect the environment from contamination.

Process and Chemical Handling

HDPE pipes are used for transporting various chemicals used in mining processes, including reagents, flocculants, and acids.

Geothermal Exchange

In some mining regions, HDPE pipes are used in geothermal exchange systems for heating and cooling mining facilities.

Reclamation

HDPE pipes can be used in reclamation efforts to restore and manage mined areas by directing water and controlling erosion.

The characteristics of HDPE pipes, including their resistance to corrosion, abrasion, and chemicals, as well as their flexibility and durability, make them a reliable choice for various applications within the mining industry. Additionally, their ease of installation and low maintenance requirements contribute to their popularity in mining operations.

BENEFITS OF HDPE PIPE FOR MINING

- Abrasion Resistance: HDPE pipes and liners are highly resistant to abrasion, making them ideal for transporting abrasive slurries and materials commonly found in mining operations.

- Chemical Resistance: HDPE is highly resistant to a wide range of chemicals, including acids and alkalis, making it suitable for handling various chemicals used in mineral processing and mining operations.

- Corrosion Resistance: HDPE pipes are immune to corrosion, making them a durable choice for applications involving exposure to corrosive substances, such as acidic or alkaline mine waters.

- Lightweight: HDPE pipes are significantly lighter than traditional materials like steel, which simplifies transportation, installation, and handling, especially in remote or challenging mining sites.

- Flexible and Tough: HDPE pipes are flexible and have excellent impact resistance, allowing them to withstand ground movement and reduce the risk of damage in rugged terrains or underground mining.

- Long Service Life: HDPE pipes have a long service life, which means they require less frequent replacement and maintenance, reducing operational costs.

- Smooth Internal Surface: HDPE pipes have a smooth internal surface that reduces friction, improving the flow of fluids, and reducing energy consumption in pumping operations.

- Leak-Proof Joints: Fusion welding of HDPE pipes creates seamless and leak-proof connections, ensuring the integrity of the pipeline.

- Quick and Easy Installation: HDPE pipes can be coiled for transport and have lightweight, flexible properties, which simplify installation, especially in challenging or remote mining locations.

- Environmental Sustainability: HDPE is a recyclable material, and the pipes can be recycled at the end of their service life, promoting environmental sustainability.

- Safety: HDPE pipes are a safer choice for personnel due to their lightweight nature and the absence of sharp edges during handling and installation.

- Low Maintenance: HDPE pipes require minimal maintenance, as they are resistant to scaling, internal corrosion, and biological growth.

- Versatility: HDPE pipes are suitable for a wide range of mining applications, including slurry transport, dewatering, water supply, chemical handling, and more.

- Reduced Transportation Costs: The lightweight nature of HDPE pipes can lead to significant savings in transportation costs, especially in remote mining sites.

HDPE PIPING in Industrial Applications

Chemical Transport

HDPE pipes are employed for transporting a wide range of chemicals and corrosive materials in industrial facilities.

Industrial Water Supply

HDPE pipes are used for providing industrial process water and cooling water.

Acid and Alkali Handling

HDPE pipes are suitable for handling acids and alkalis in industrial settings due to their chemical resistance.

Compressed Air Systems

HDPE pipes are used for compressed air distribution systems in industrial plants.

Industrial Wastewater

HDPE pipes are used to transport industrial wastewater, which may contain various chemicals and contaminants.

Slurry Transport

In mining and industrial settings, HDPE pipes are used to transport abrasive and corrosive slurries.

Power Plant Applications

HDPE pipes are used in power plants for cooling water, process water, and effluent transport.

Industrial Cooling Systems

HDPE pipes are used in cooling systems for industrial machinery and equipment.

Food and Beverage Industry

HDPE pipes are used for conveying various fluids and materials in the food and beverage industry due to their food-grade qualities.

Oil and Gas Processing Facilities

HDPE pipes are used in industrial facilities for transporting oil, gas, and various fluids, particularly in the downstream sector.

BENEFITS OF HDPE PIPE FOR INDUSTRIAL APPLICATIONS

- Chemical Resistance: HDPE pipes are well-suited for transporting a wide range of chemicals, acids, and corrosive materials commonly used in industrial processes.

- Abrasion Resistance: In applications involving abrasive materials or slurries, HDPE pipes are resistant to abrasion, ensuring long-term reliability.

- Temperature Tolerance: HDPE pipes can handle a wide range of temperatures, making them suitable for applications involving hot or cold fluids.

- Smooth Interior Surface: The smooth interior surface minimizes friction and pressure losses in industrial fluid transport.

- Impact Resistance: HDPE pipes are robust and can withstand impacts, making them suitable for use in industrial facilities where accidental damage is possible.

- Lightweight and Easy Handling: The lightweight nature of HDPE pipes simplifies transportation, handling, and installation, reducing labor and equipment costs.

- Cost-Effective: Lower maintenance and replacement costs, along with reduced energy consumption, make HDPE pipes a cost-effective choice.

- Environmental Sustainability: HDPE is recyclable and contributes to sustainability goals in industrial settings.

- Versatility: HDPE pipes can handle a variety of fluids, including water, chemicals, slurry, and process waste, making them a versatile choice for different industrial applications.

GET IN TOUCH

Ready to supercharge your mining operations with the advantages of HDPE piping? Contact our experienced sales representatives now to explore how our solutions can enhance durability and cost-efficiency in mining and industrial applications.

Forward Thinking,

Forward Driven,

Indigenous Business Partnerships

With pride, professionalism, and precision as our foundation, we connect industry partners with our Indigenous community to bring sustainable success and growth across nine different divisions.

“kahmiyo skwichis piyo” – To work together

Industries & Applications

Our Office

Contact Information

- Phone: 825-901-2700

- Email: sales@alexandertubular.ca

Address

- 3052 84 Avenue

- Edmonton, AB T6P 1K3

Hours of Operation

- Monday: 8:00 AM – 4:30 PM

- Tuesday: 8:00 AM – 4:30 PM

- Wednesday: 8:00 AM – 4:30 PM

- Thursday: 8:00 AM – 4:30 PM

- Friday: 8:00 AM – 4:30 PM

- Saturday: Closed

- Sunday: Closed